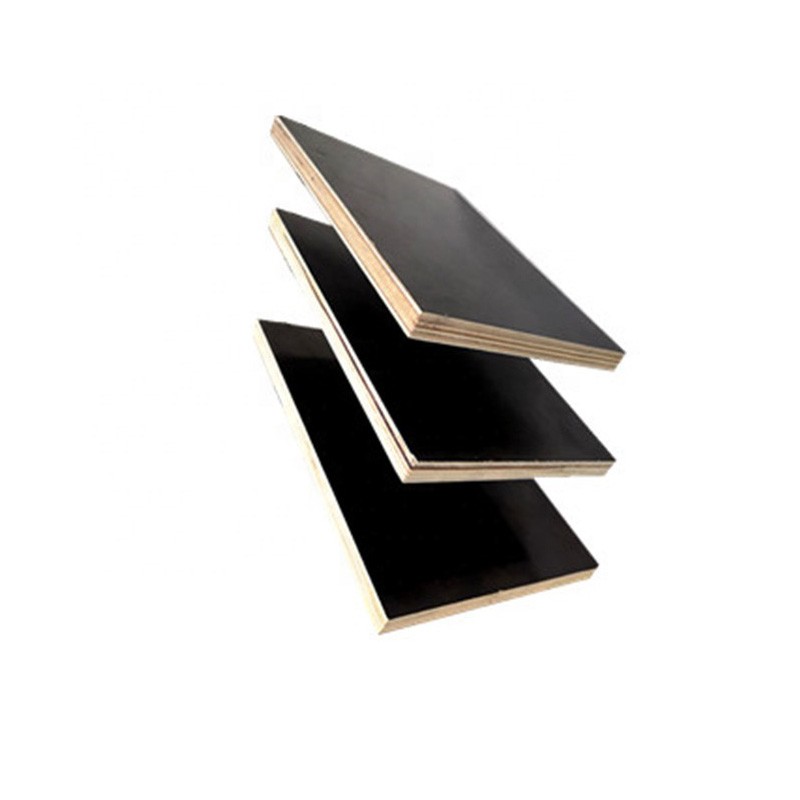

FILM FACED PLYWOOD

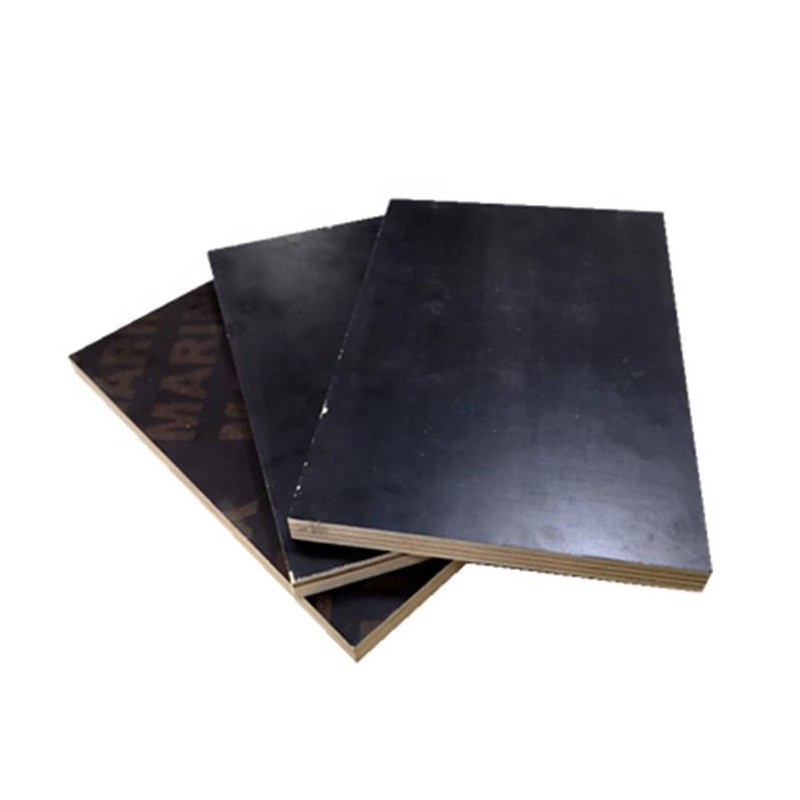

1.No wapping, no fracture, not out of shape, it can stay 24 hours in boiling water.

2.Good performance and more turnover use time.

3.It is easy to take off the membrane;Time is only 1/7 of the steel mould.

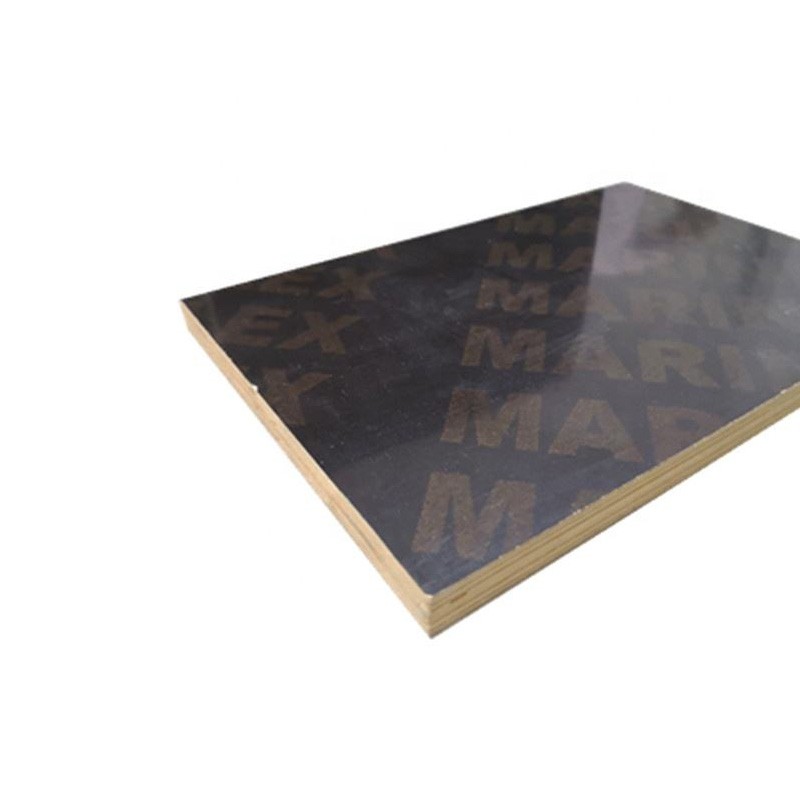

4.Make the surface of concrete more smooth and beautiful, so it can be easy to make decoration and it also deduct the processing of plastering.

5.This can moderate and contact 30% time for a project.

6.Corrosion resistant and it will not pollute the surface of concrete.

7.It is good to keep performance warm, is favorable to make construction in winter.

8.Products can be made into warping plywood.

9.It is better to nail,saw,drill than bamboo and steel mould, it can be processed into different types.

Film faced plywood is an W.B.P phenolic plywood covered with waterproof surfaces. A resistant and economical material that professionals can use for their building projects and civil works.

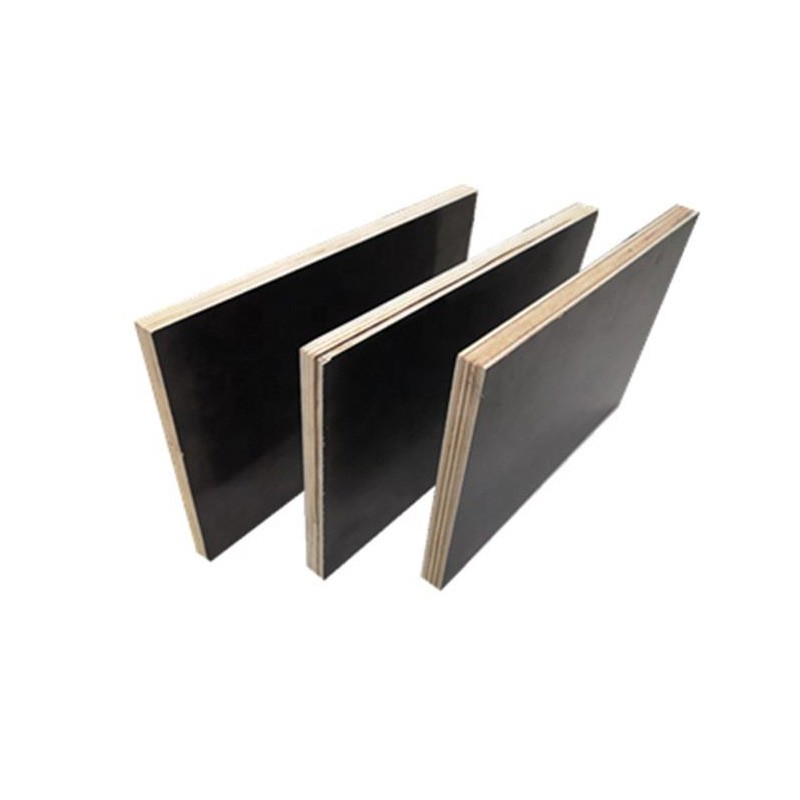

Item | Film faced plywood, Construction plywood, Form-work plywood |

Film | Brown film, Black film, Red film, green PP plasctic,Anti-slip film, with logo |

Core | Poplar, hardwood, combi, finger-joint core |

Hot press | 1 time or 2 times |

Glue | melamine WBP, phenolic WBP |

Size | 1220×2440mm,1250×2500mm or as requirement |

Thickness | 9mm, 12mm,15mm, 16.5mm, 17mm, 17.5mm, 18mm |

Thickness tolerance | +/- 0.5mm |

Density | 500-600 KGS/CBM |

Moisture | To be 6%-14% at time of shipment |

Usage | Construction, form-work |

Film faced plywood is a type of plywood that has a film coating on the surface. This film coating, usually made of plastic or resin material, helps to protect the plywood from moisture, rot and other damage. The film coating also helps to make the surface of the plywood smoother, which makes it easier to work with. Laminated plywood is often used in construction and furniture manufacturing because it is both strong and durable.

FILM FACED PLYWOOD

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q3:Is OEM service available?

A3:Yes,customers design, color,logo is welcome and available. With advantages of local industries, we have designed and OEM for many brand.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.